New Energy Battery Packs

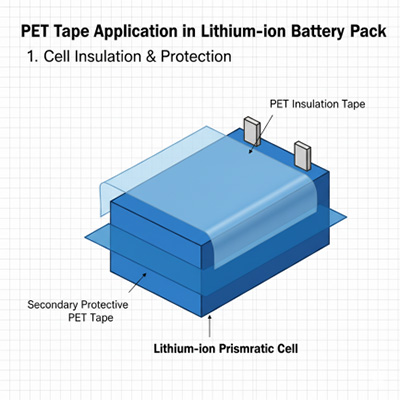

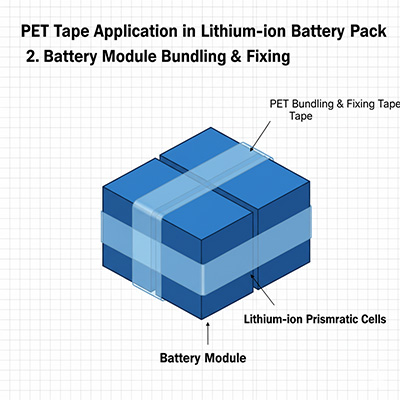

During the operation of new-energy lithium-ion battery packs, significant heat is generated. Therefore, all tapes used internally must possess certain heat resistance, with specific critical areas requiring both high-temperature resistance and flame retardancy. Additionally, components and wiring in the core operational areas require insulation protection to prevent internal short circuits. PET tape offers commendable performance in both these aspects.

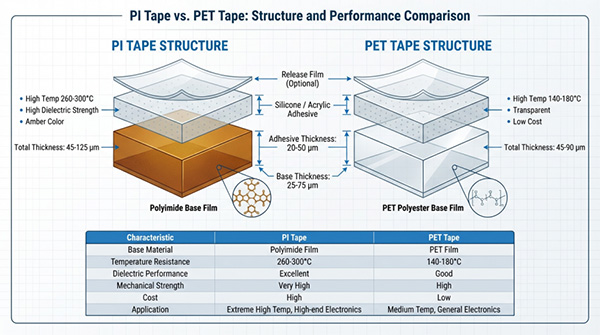

The backbone of PET is composed of alternating benzene rings and ester bonds. The benzene ring, as a stable functional group, provides substantial rigidity and strength, while the ester bond contributes a degree of flexibility. Consequently, PET tape combines good rigid physical properties with certain flexible characteristics, such as extensibility and relative softness. It also exhibits high thermal stability, thanks to its stable molecular structure, enabling it to withstand certain high temperatures. The dense molecular structure results in high dielectric strength and a high breakdown voltage for PET tape, making it commonly used for insulating wraps between battery cells and for the insulation and securing of wire harnesses. Its high tensile strength provides excellent fixation for structural components. Furthermore, its edge protection capability is significant, with outstanding abrasion resistance, often employed to mitigate risks associated with "friction - wear-through - short circuit."

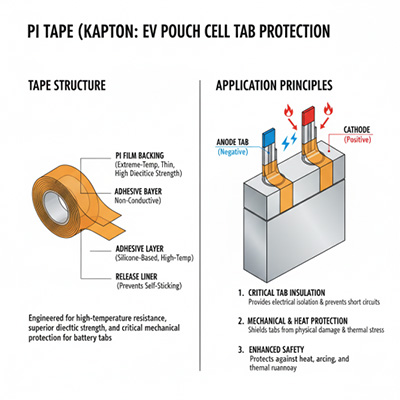

PI tape is polymerized from monomers containing imide rings and benzene rings. The imide rings and benzene rings form a conjugated system, creating a highly rigid structure where internal molecular space is compressed, and molecular chain rotation is greatly restricted. This results in superior internal stability compared to PET tape, along with generally better overall performance. PI tape outperforms PET tape in thermal stability, flame retardancy, and performance in high-temperature and high-humidity environments. Its glass transition temperature is significantly higher than that of PET tape, making it suitable for use in core high-temperature areas of battery cells. PI tape also has a high Limiting Oxygen Index (LOI), making it inherently flame retardant. Thus, it is one of the key tapes for thermal runaway protection in battery packs.

In summary, both PI tape and PET tape play vital roles in power battery packs, each serving important functions in different areas. They are used for tab edge sealing and insulation protection in pouch cells to prevent welding splatter. PI tape offers better resistance to electrolyte corrosion and higher chemical stability. However, its cost is considerably higher compared to PET tape.