Packaging

In modern packaging systems, tape is not only the final step in sealing boxes but also a critical material ensuring packaging integrity and logistics safety. From production line packing and warehouse handling to cross-regional transportation and end delivery, every stage relies on tape for fixation, sealing, reinforcement, and protection. It stabilizes packaging structures, enhances packaging efficiency, and safeguards transport safety, serving as a key bridge connecting products to customers.

Packaging tapes must exhibit excellent physical properties. They need to be soft yet sufficiently tough, adhering smoothly without lifting or buckling on bends, corners, and non-linear surfaces, thanks to high-performance adhesives. During transport and storage, they must withstand friction and impacts while maintaining integrity without tearing or damage.

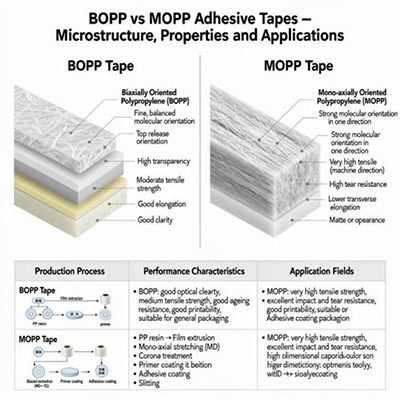

Both BOPP and MOPP tapes are polypropylene-based films—one biaxially oriented, the other uniaxially oriented. Both types demonstrate outstanding physical and chemical properties. BOPP tape offers high tensile strength, high elongation, sufficient rigidity, and toughness, making it resistant to damage. The polypropylene film features high and stable molecular weight, excellent weather resistance, moisture barrier properties, aging resistance, and resistance to acids, alkalis, and UV radiation. Its high transparency ensures that product information on packages remains visible. Commonly used for protecting and packaging everyday items, BOPP tape is the most widely used product in express parcel services.

MOPP tape, due to its uniaxial orientation, provides even higher tensile strength, lower elongation, and greater resistance to deformation compared to BOPP. This makes it ideal for heavy-duty bundling and securing internal components of appliances like refrigerators and washing machines. As a higher-strength industrial-grade tape, it is significantly more expensive than cost-effective BOPP tape.

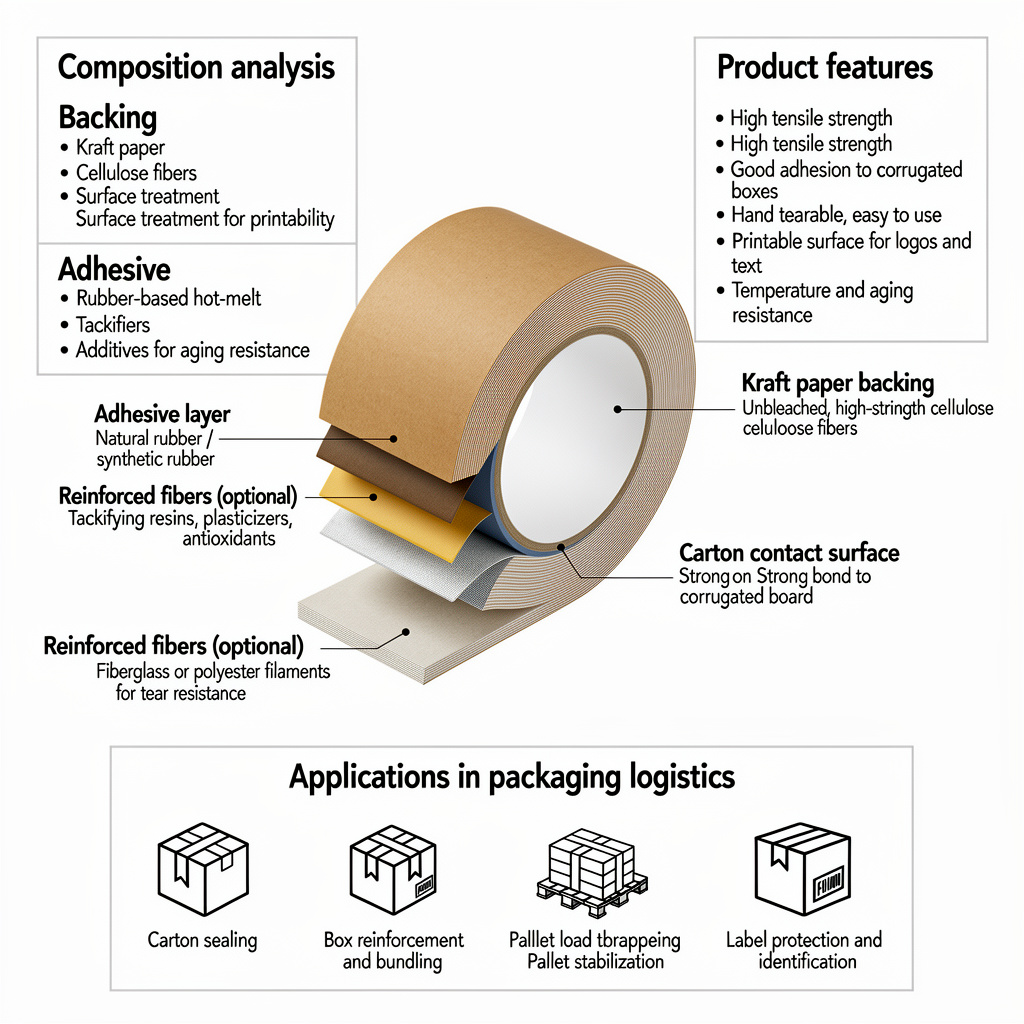

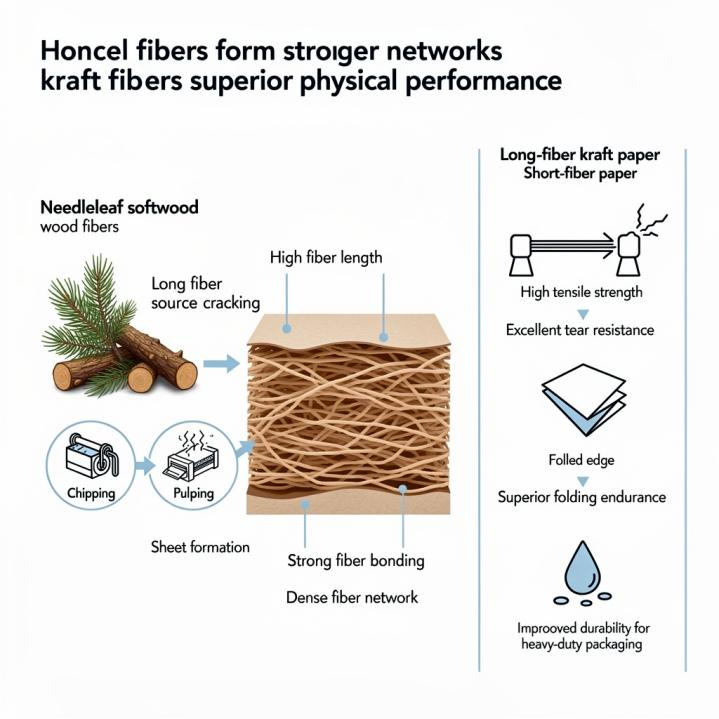

Kraft paper tape holds a substantial share in the packaging industry. Made from long-fiber softwood pulp and produced using the kraft process, it retains internal fibers better, resulting in superior toughness and enhanced physical properties compared to regular paper. It excels in tensile strength, tear resistance, and abrasion resistance. With waterproof surface treatment, its protective performance is comparable to polypropylene tapes. The relatively rough surface of kraft paper forms strong bonds with adhesives, ensuring excellent initial tack and adhesion to corrugated surfaces. It also offers high printability, making it suitable for corporate or custom logos. Environmentally, kraft paper tape has significant advantages: versions without plastic or silicone coatings are biodegradable and recyclable. Water-activated kraft paper tape uses starch-based adhesives, making both the substrate and adhesive eco-friendly. Like OPP tape, it is suitable for sealing and protecting various types of packages, reinforcing box strength, increasing load capacity, and enhancing structural integrity. With growing global environmental awareness and regulations, kraft paper tape has become an important alternative to OPP tape.

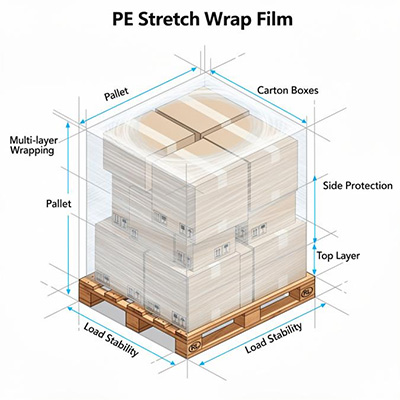

PE tape, similar to OPP tape, is a polymer-based tape but offers very high elongation, often ≥300%. It also provides excellent weather and temperature resistance. PE stretch film is the optimal choice for wrapping large palletized goods. When stretched and wrapped multiple times, it forms a strong, protective layer that shields contents and blocks moisture. Its soft, flexible nature allows it to conform perfectly to irregularly stacked cargo and cartons, making it an ideal packaging tape.