HVAC & Pipe Protection and Insulation

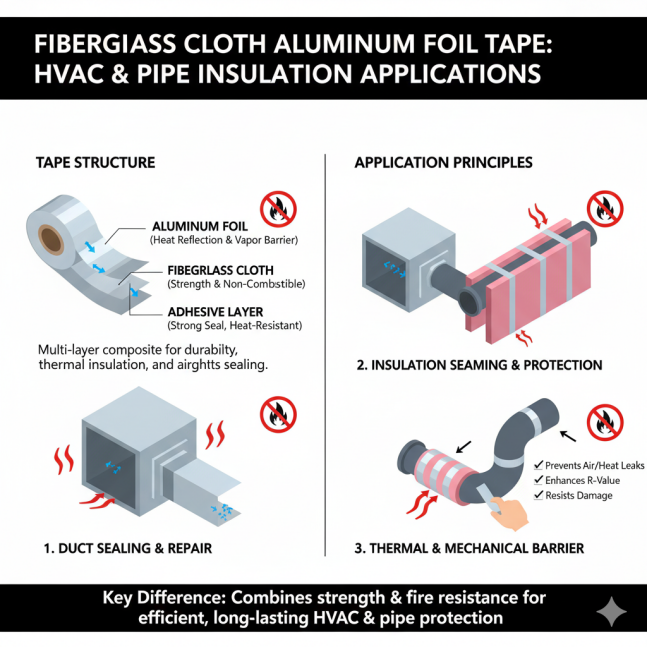

In HVAC and pipeline insulation systems, airtightness, thermal insulation, and moisture resistance are key performance indicators. As an essential auxiliary material for connection, sealing, and reinforcement, tape directly impacts the overall insulation efficiency, airtightness, and safety of the system.

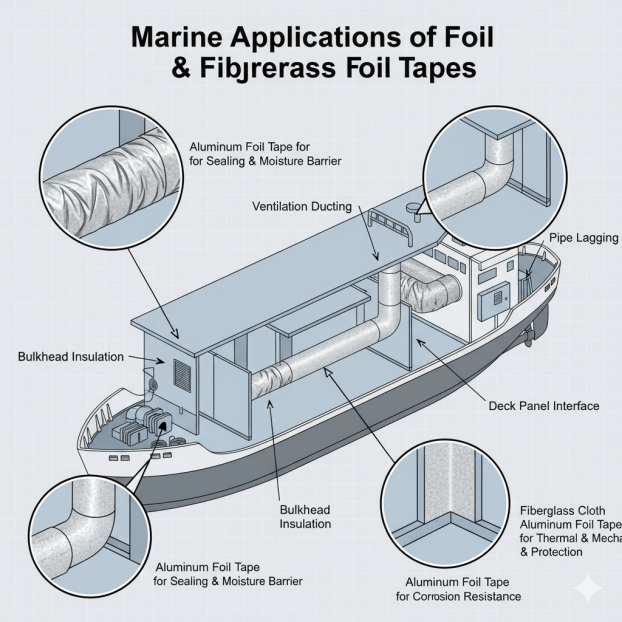

Aluminum foil tapes and composite aluminum foil tapes are widely used in HVAC and pipeline protection applications. This is primarily because aluminum foil exhibits excellent thermal radiation reflectivity, significantly enhancing insulation performance. The outermost layer of pipeline repair points is often wrapped with aluminum foil tape, serving not only as a fixing and protective component but also leveraging the superior thermal conductivity of aluminum as a metal. This ensures the normal operation of pipeline functions while minimizing heat loss during thermal transfer. Additionally, metal aluminum foil is dense and non-porous, providing waterproof and moisture-proof functions with 100% vapor barrier capability, playing a critical role in pipeline protection.

Pure aluminum foil tape is arguably the best metal aluminum tape for insulation applications. Aluminum is a relatively soft metal, offering certain ductility, which allows it to be tightly wrapped around pipes and corners at various angles.

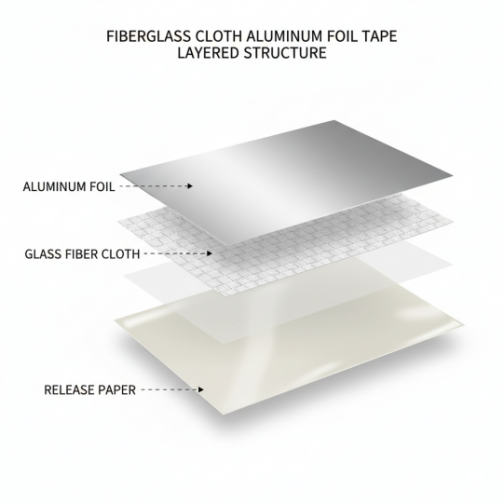

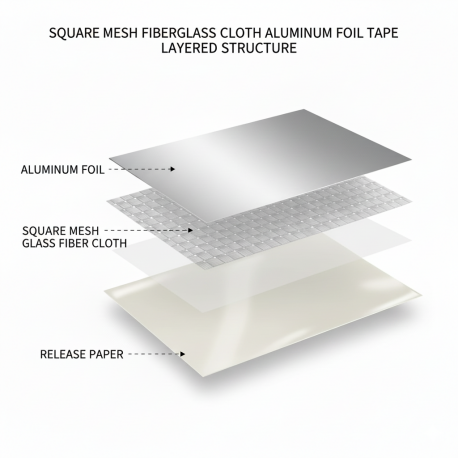

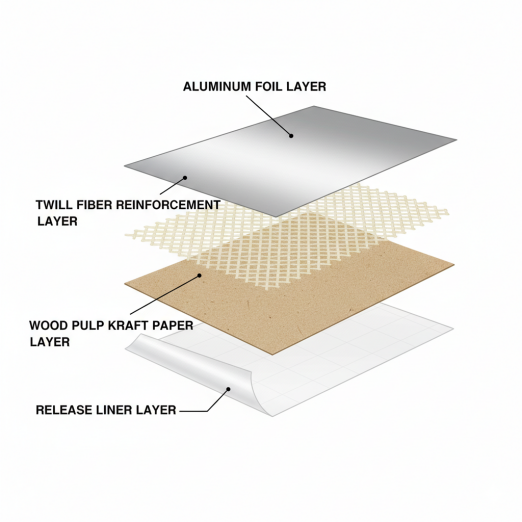

However, pure metal aluminum foil is relatively thin, resulting in insufficient tensile strength and toughness. To enhance its applicability in this field, it is often combined with other composite materials to address these limitations, such as polyester fibers or fiberglass. One is a polymer molecular fiber, the other is a silicate compound fiber. Both significantly improve the physical properties of aluminum foil insulation materials, greatly enhancing tensile strength in both longitudinal and transverse directions. This approach preserves the advantages of aluminum foil while compensating for its weaknesses, thereby extending service life and broadening application scope. Based on differences in composite fiber density and material, they can be categorized as reinforced aluminum foil tape, scrim-reinforced aluminum foil tape, and fiberglass cloth aluminum foil tape. Reinforced and scrim-reinforced aluminum foil tapes, with relatively lower fiber density, offer better flexibility and are suitable for complex corner applications and non-linear adhesion, providing effective protection for pipelines with intricate angles. Fiberglass cloth tape, with its high fiber density, offers greater rigidity and performs better in insulation and protection for straight pipelines.

Fiberglass cloth aluminum foil tape, composed of fiberglass and aluminum foil, demonstrates remarkable performance in flame retardancy due to the very high ignition points of both materials. Thus, it not only enhances pipeline insulation and protection but also reduces fire safety risks. When combined with flame-retardant adhesives, aluminum foil tapes can be applied in fire protection and flame retardancy applications.