Spray Masking

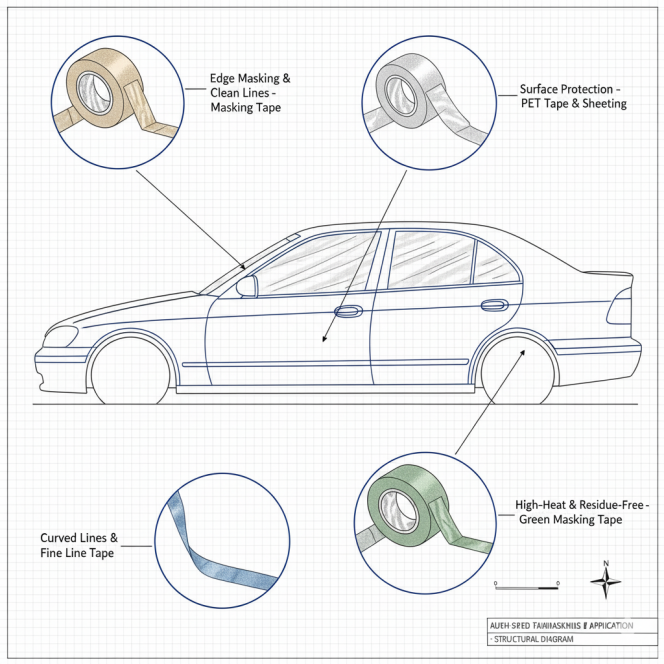

Tape is a simple, efficient, and low-cost material used in spray masking to create a physical barrier and achieve sharp paint lines. It can be easily removed after spraying without affecting the appearance of the substrate.

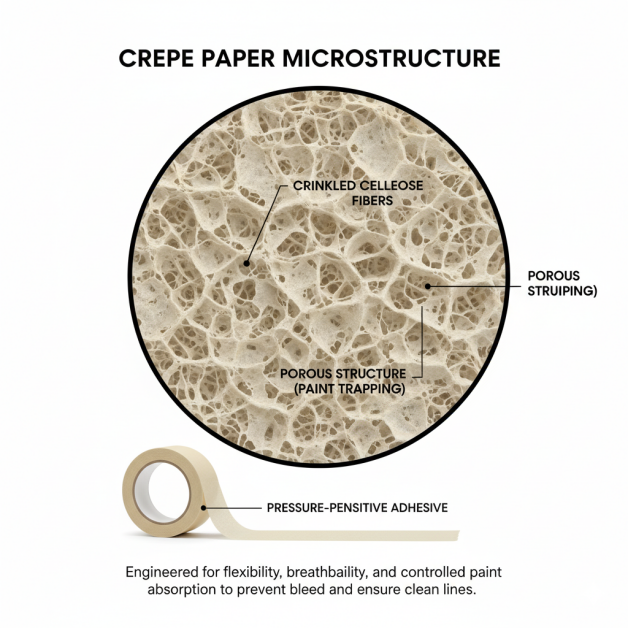

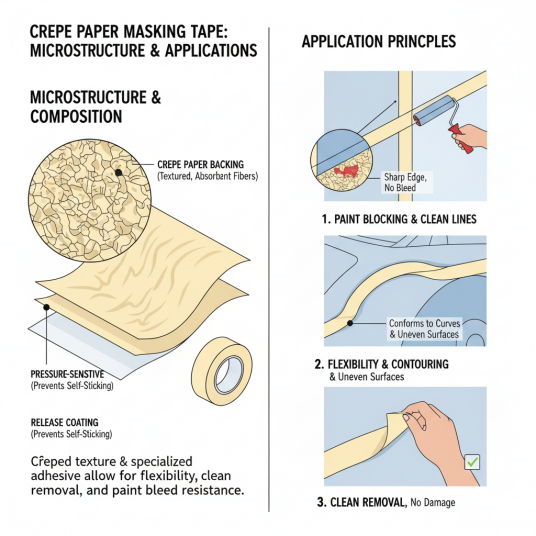

Made from randomly interwoven cellulose fibers, masking tape forms a porous and compressible mesh structure. This gives it excellent flexibility and the ability to conform to curved surfaces. After surface treatment, it resists bleeding with most paints and inks (both oil-based and water-based). The breathable microporous structure allows the coated adhesive to penetrate the paper base, creating an anchoring effect. As a result, when removed, the adhesive tends to bond more strongly with the masking paper, preventing residue on the substrate and ensuring a perfect paint finish. Due to its low cost, masking tape is widely used in various spray masking applications, such as defining paint boundaries in automotive painting, and delimiting surfaces for painting furniture and walls in the home decoration industry, as well as protecting adjacent materials during paint spraying.

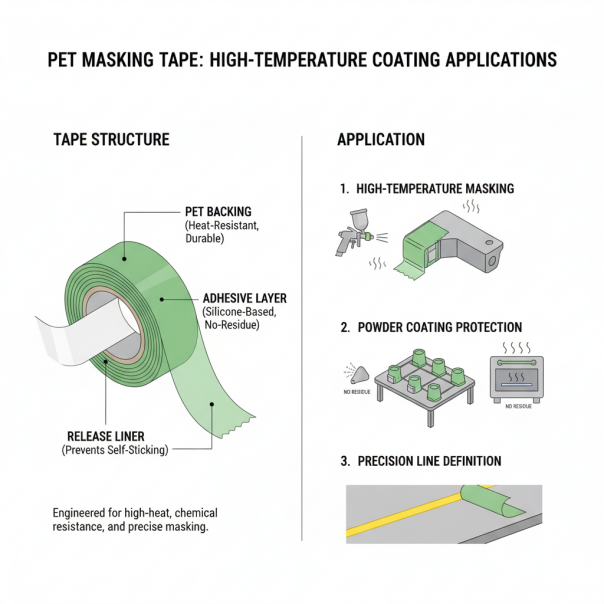

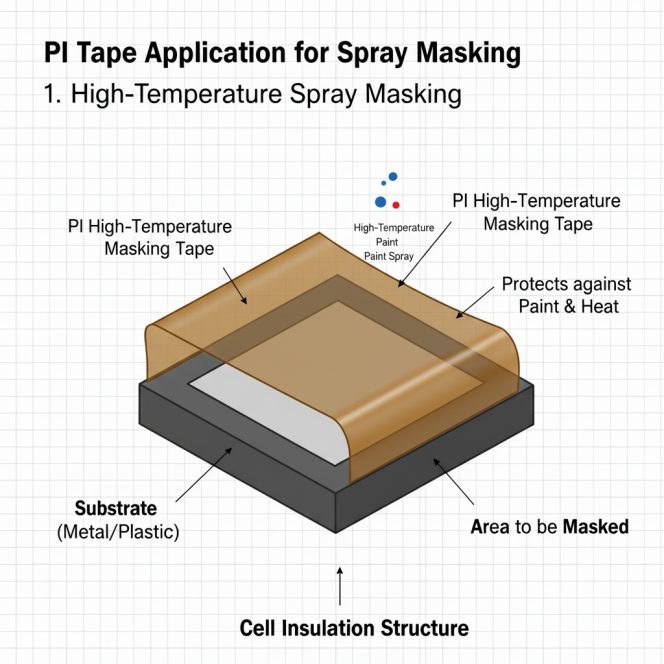

Pet tape offers excellent heat resistance, low thermal shrinkage, high tensile strength, and solvent resistance. It is an essential masking tape for high-temperature spray applications. Additionally, PET exhibits strong adhesion with the adhesive, ensuring no residue is left upon removal. PET tape with conventional acrylic adhesive can withstand temperatures of up to approximately 120°C, making it suitable for many precision high-temperature paint spraying industries, such as automotive manufacturing, aerospace coating masking, and precision electronic housing spraying. Silicone-based PET tape offers significantly improved heat resistance, reaching 150°C or even 180°C. PI tape is an upgraded version of PET tape, with enhanced performance across all properties. However, due to its considerably higher cost compared to PET tape, it is typically used only in extremely demanding spray applications.

Aluminum foil tape is less commonly used in the spray industry but still finds some applications. The excellent heat radiation reflection of aluminum foil helps protect substrates from overheating during masking. It offers outstanding heat resistance and maintains performance without degradation during prolonged spraying tasks. The dense metal structure provides complete protection to the masked surface.