Fire Protection

Large-scale infrastructure equipment operates in complex environments with multiple interconnected systems. This necessitates the use of auxiliary structural components with sufficient safety performance to ensure normal equipment operation and the ability to prevent or mitigate incidents under special circumstances. Data center equipment consistently operates at high temperatures, while ventilation ducts and smoke stacks endure prolonged high heat and humidity. Cable areas experience temperature increases due to heavy loads, and air conditioning condensation leads to elevated moisture levels. Outdoor equipment faces continuous UV exposure. Under these demanding conditions, auxiliary materials must provide adequate protection when problems occur.

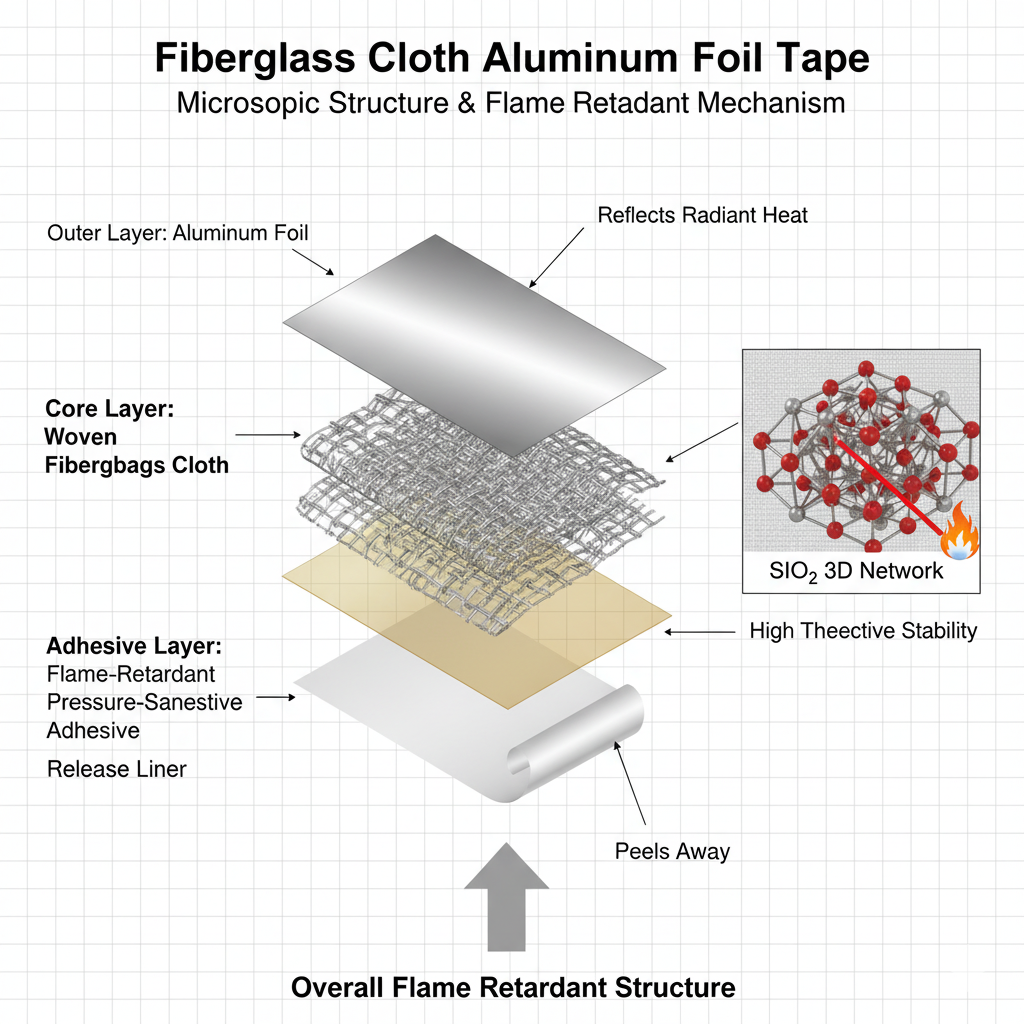

Aluminum foil tape and fiberglass aluminum foil tape are widely used for fire prevention in pipelines. Aluminum reflects 95% of infrared heat, reducing thermal conduction while maintaining excellent thermal conductivity, which prevents heat accumulation and potential spontaneous combustion. The dense metal layer also acts as an oxygen barrier, limiting fire-oxygen contact. Fiberglass aluminum foil tape combines aluminum with silicon oxides. The Si-O-Si bond possesses high energy, and silicon oxides/silicates have exceptionally high ignition points, making them resistant to combustion and fire escalation. This combination allows fiberglass aluminum foil tape to provide superior fire protection compared to standard aluminum foil tape.

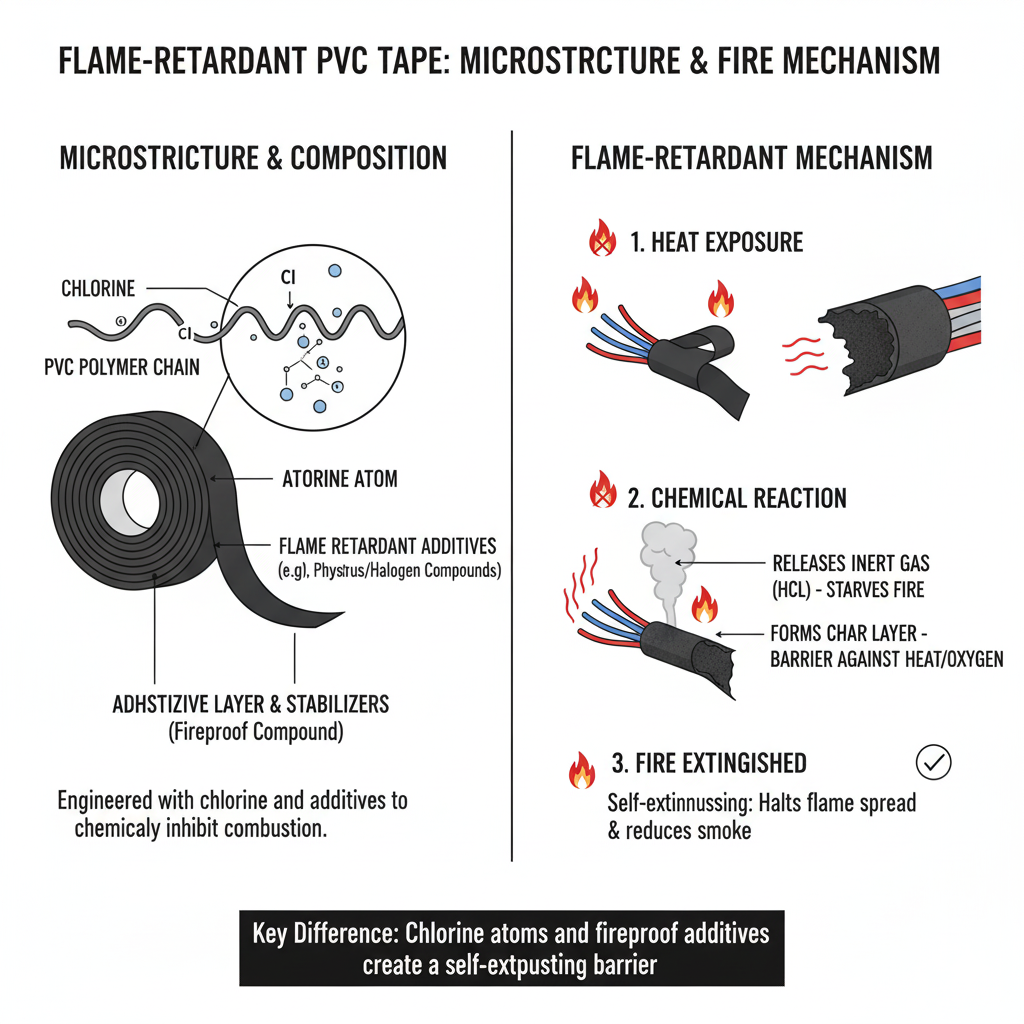

PVC tape uses polyvinyl chloride film as its base material. Its molecular structure contains numerous chlorine atoms. When exposed to flame, PVC generates HCl gas, where halogen gases dilute combustible gas concentrations and absorb heat to interrupt combustion. Chlorine release causes structural carbonization, further isolating oxygen and heat. During production, flame retardants like Sb₂O₃ are often added to PVC. This substance reacts with HCl generated during combustion to form SbCl₃, which, being dense, covers surfaces and blocks air access, creating synergistic flame-retardant effects.

Compared to PET or PI tapes, PVC's molecular spatial structure is less orderly, and the inclusion of plasticizers makes the material softer with lower rigidity than these alternatives. This flexibility enables smooth application in wire harness wrapping and fixation. Combined with its excellent insulation properties, PVC tape becomes the ideal choice for cable electrical insulation and flame retardancy.