Home Appliance Industry

In the refrigerator manufacturing process, various types of tapes play indispensable auxiliary roles. Refrigerators are among the most environmentally complex appliances in modern households, with internal conditions including low temperatures, high humidity, condensation, and cyclical temperature changes. Therefore, the tapes used are specially designed and rigorously tested functional products.

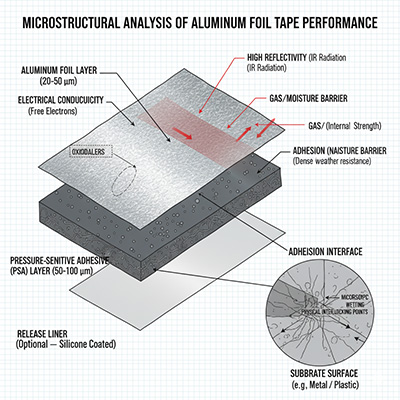

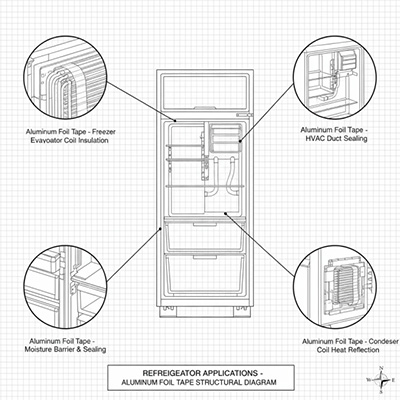

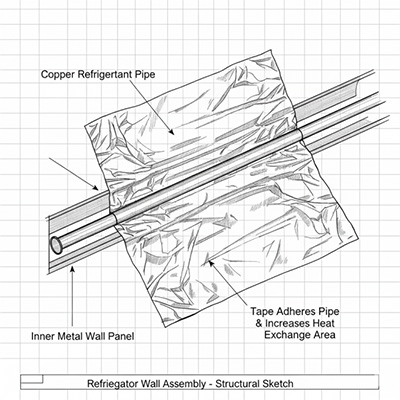

Aluminum foil tape is the most critical tape in refrigerators. Its excellent thermal radiation and conductivity help maintain the stable structure of the internal evaporator and condenser during alternating cold and heat cycles. It also secures and protects various components, including refrigerant pipelines and core electrical parts. The tape bonds firmly with polyurethane (PU) foam, which is a highly effective thermal insulation material that minimizes heat exchange and maintains the condenser tubes at an ultralow temperature. However, PU foam can be corrosive and may affect condenser tubes (copper tubes). Here, aluminum foil tape provides essential protection, often combined with a polymer film coating. This dual-layer protection prevents damage from PU foam to internal parts while ensuring the aluminum foil substrate remains stable and does not degrade over long-term exposure to low temperatures. Innovations such as liner-free aluminum foil tapes eliminate the need to remove release paper, speeding up production and reducing environmental waste from non-biodegradable release paper.

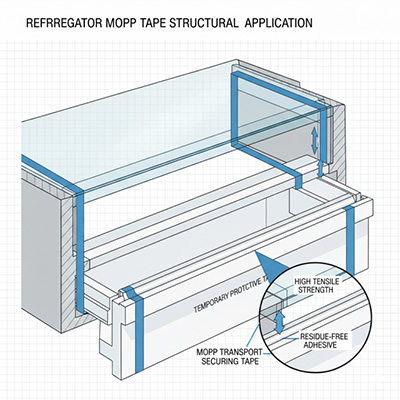

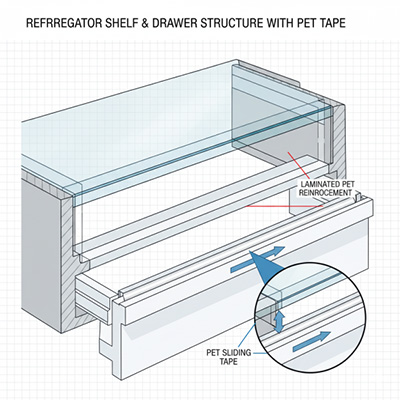

PET and MOPP tapes are crucial for securing internal cabinets and compartments due to their high tensile strength and flexibility. Their strong adhesion keeps refrigerator interiors stable under various external forces, preventing damage during production or logistics. These tapes can be removed without leaving adhesive residue, maintaining a clean appearance.

PE tape offers excellent elongation, making it suitable for protecting electrical components at bends and corners inside refrigerators. When coated with special surface treatments, it bonds effectively with PU foam, serving as a cost-effective alternative to aluminum foil tape with better flexibility, though it provides inferior protection and thermal conductivity.

Double-sided foam tape is often used instead of fasteners or liquid adhesives for mounting refrigerator glass doors and attaching nameplates and labels. It provides excellent stress dissipation, protecting adhered surfaces, and offers durable, stable bonding.

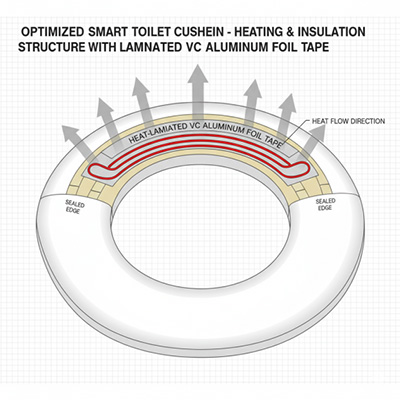

Heat-sealable VC Aluminum Foil Tape is coated with a vinyl copolymer on the aluminum foil surface. Under heat, it undergoes a thermal bonding reaction with other components, resulting in an adhesion that is more stable and robust compared to pressure-sensitive adhesives. Depending on the cross-linking agents used in the coating, the heat-sealing temperature can range from as low as 70–80°C up to 200–230°C. Low-temperature heat sealing is suitable for applications such as medicine bottle sealing, while high-temperature sealing can be used for fixing heating wires in smart toilet seats.